Oil Based Curing compound Polywed

Curing beton adalah metode yang lebih dipahami sebagai perawatan beton. Struktur beton umumnya bersifat cepat mengeras dan mudah mengering, oleh karena itu curing beton dilakukan agar kadar air pada beton tidak cepat berkurang sehingga menghasilkan beton bermutu baik. Perawatan beton ini dilaksanakan ketika permukaan beton yang terbuka telah.

Curing Compounds Tremco Australia

Ben E. Edwards R. Doug Hooton Jerome H. Ford. This guide reviews and describes practices, procedures, materials, and monitoring methods for the external curing of concrete and provides guidance for specifying curing procedures. Current curing techniques are presented and commonly accep ted methods, proce-dures, and materials are described.

Curing Beton Pengertian, Fungsi, & Metodenya Geosinindo

A: A concrete curing compound is a material applied to the surface of freshly-poured concrete to help it retain moisture and achieve optimal strength and durability. Curing compounds are designed to form a protective barrier or penetrate the concrete, helping to prevent moisture loss and promoting the proper curing of the concrete.

CURING COMPOUND FOR CONCRETE, DIFFERENT TYPES OF CURING COMPOUNDS, WHAT ARE CURING COMPOUNDS

curing compounds or evaporation reducers for improving the cure of the concrete. Silicates do not provide the two primary functions required of a concrete curing compound: they do not form a continuous film on the concrete surface and they do not retain moisture to promote proper cement hydration.

NEWLY RELEASED DUALACTION ACRYLIC CURING COMPOUND W. R. Meadows

Metode curing ini bisa dilakukan dengan cara menyiram air, menutup permukaan beton dengan bahan penutup, atau menggunakan bahan kimia curing compound. Tujuannya adalah agar beton tetap lembab dan tidak cepat mengeras sehingga dapat terhindar dari keretakan yang tidak diinginkan. 3. Melindungi Beton dari Pengaruh Cuaca Ekstrem

Liquid Curing Compound, Rs 186 /litre Perma Construction Aids Private Limited ID 7401966133

The effectiveness of curing compounds is defined as their ability to prevent the evaporation of water from fresh concrete under defined temperature and humidity conditions. The most widely used methods are PKN-CEN/TS 14754-1, similar to ASTM C156 and AASHTO T 155 [ 17, 18, 23 ].

Water Based Curing compound Polywed

Curing compound shall comply with ASTM C309 4 or ASTM C1315 5. 3) Accelerating strength gain using heat and additional moisture. Live steam Live steam at atmospheric pressure and high-pressure steam in autoclaves are the two methods of steam curing. Steam temperature for live steam at atmospheric pressure should be kept at about 140 degrees.

Water Based Concrete Curing Compound For Construction at Rs 100/kg in Nagpur

Curing compound adalah bahan yang digunakan untuk mempercepat proses pengerasan beton pada suatu proyek konstruksi. Di Indonesia, ada beberapa jenis curing compound yang dapat digunakan untuk mempercepat proses pengerasan beton, dan di bawah ini adalah jenis-jenis curing compound tersebut beserta kelebihannya. 1. Curing compound film-forming

.jpg)

AMITEK RESIN WATER BASED CURING COMPOUND

Memungkinkan untuk dilakukan curing dini dengan diaplikasikan segera setelah bleed water tidak tampak dan kilau air menghilang. 2. Tersedia dalam warna reflektif matahari untuk mengurangi panas permukaan melalui pemantulan. 3. Menjadi solusi di tempat yang kekurangan atau tidak tersedia air. 4. Bisa diaplikasikan untuk permukaan beton vertikal. 5.

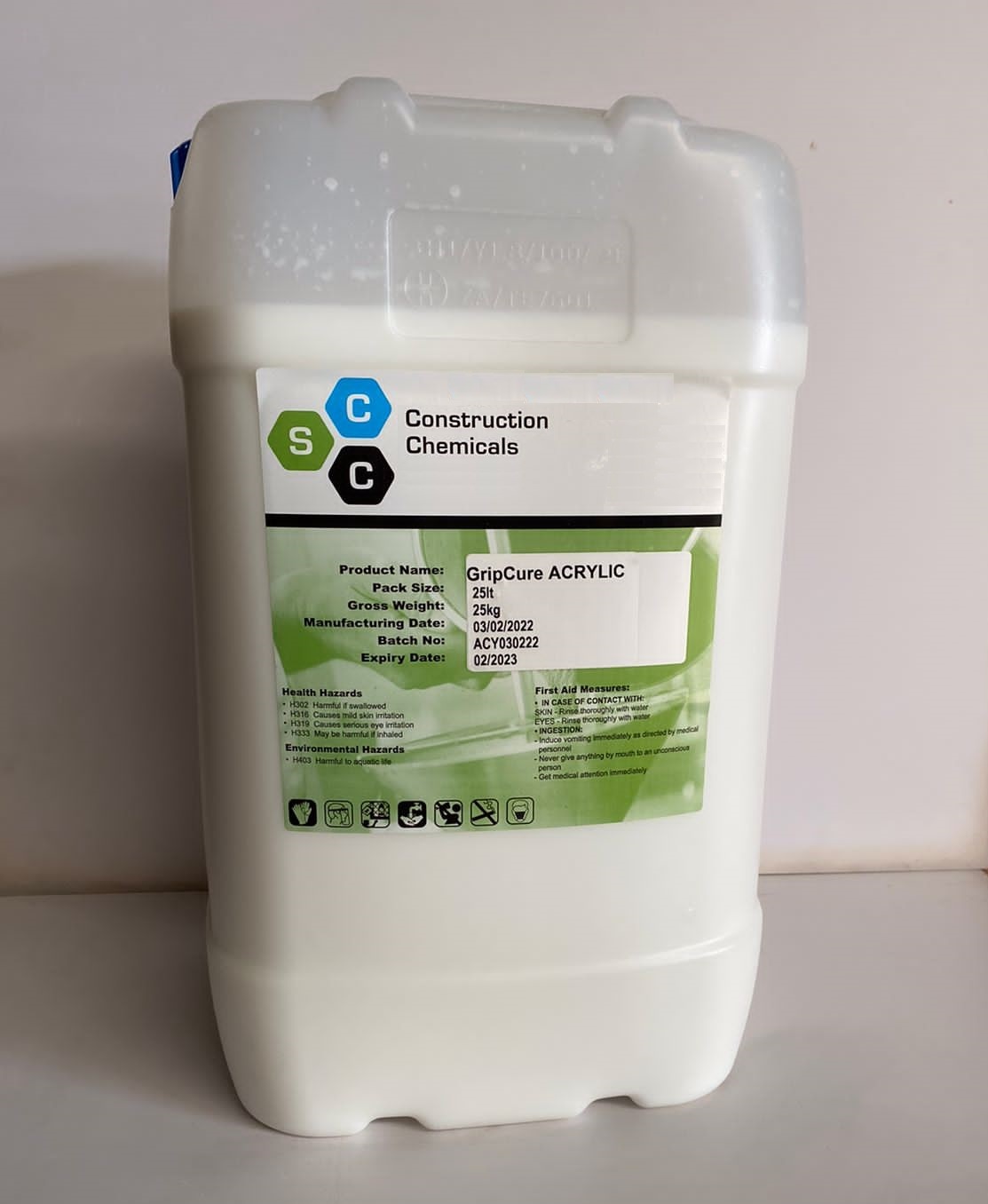

Concrete Curing Compound Definition, Types, Application & Uses

Scope. 1.1 This specification covers liquid membrane-forming compounds suitable for application to concrete surfaces to reduce the loss of water during the early-hardening period. White-pigmented membrane-forming compounds serve the additional purpose of reducing the temperature rise in concrete exposed to radiation from the sun.

Jual Sika Antisol S Curing Compound di Lapak Pasti Jaya Semarang Bukalapak

The technology of the curing compound affects its ability to retain moisture. Curing compounds are classified according to the requirements of AS3799. To comply with AS3799, curing compounds must retain >90% of the original water in concrete over a 72 hour test (Curing Efficiency), not all available technologies will achieve this. The graph.

XDS Curing Compound Danterr Construction Products

The compound should be applied at a uniform rate. The usual values for coverage range from 0.20 to 0.25 m2/lit. Curing compound can be applied in two applications at right angles to each other by hand or power sprayer usually at about 0.5 to 0.7 MPa pressure.

Curing Compounds

The curing compound is applied through spraying pipe as shown in above figure with constant rate of pressure. Generally, one liter of curing compound can be sprayed for 0.20 - 0.25m 2 surface area of fresh concrete. The sprayer pressure is usually 0.5 - 0.7 MPa. In small areas, we can also use brushes or paint rollers to apply curing compounds.

RMCS Concrete Curing Compound 200Litres = CC200L Rebar, Mesh and Construction Supplies (Pty) Ltd

Wax Cures. Purpose: These curing compounds work by forming a water-resistant barrier on the concrete surface. The wax film not only aids in retaining moisture but also offers a shine to the concrete surface. Product Selection: Wax cures are ideal for surfaces where a glossy finish is desired.

Curing Compound Ecoratio

Curing compounds (cures) are liquid membrane-forming compounds that reduce moisture loss in the early hardening period when applied to fresh concrete. A curing compound helps retain moisture in the concrete, improving hydration. This improved hydration produces a stronger, denser concrete substrate when compared to improperly or uncured concrete. The curing compound is considered a temporary.

Concrete Curing Compounds Winchem

Tujuannya adalah untuk mencegah agar air pada beton tidak menguap dengan cepat. Penguapan pada beton. Aplikasi dan cara curing beton ini dilakukan pada wilayah yang cenderung dingin atau memiliki musim dingin. Caranya adalah dengan proses steam di mana beton harus dipertahankan dulu pada suhu 10 hingga 30 derajat cecius selama berjam-jam.